February 12, 2020

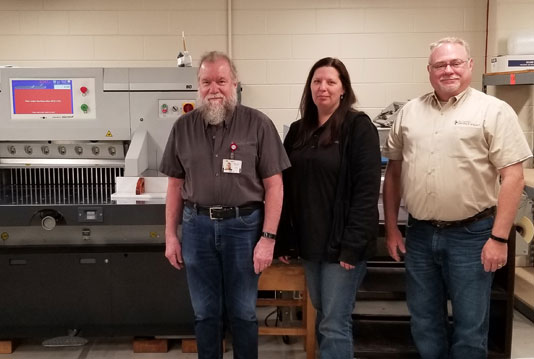

Microcut® automation gains keep Graphic Partners with Colter & Peterson

A Chicago area printer recently bought both a new and used paper cutter because of their familiarity with and faith in Microcut. Over the years, Graphic Partners has seen enhanced paper cutter output thanks to Microcut® automation. Their new SABER with Microcut PLUS now handles the bulk of the work in their finishing department.

READ MORE

March 11, 2019

Visit Colter & Peterson at ICE USA 2019 in Booth 542

Colter & Peterson will be in Booth 542 at ICE, the International Converting Exhibit and trade show in Louisville. We’ll be talking about CHM Precision Sheeters, paper cutters and paper handling equipment. The show will be April 9th to 11th. Stop by.

READ MORE

January 29, 2019

Norka gets down to business with new Colter & Peterson CHM precision sheeter

As a mid-size specialty converter of paperboard packaging and paper, being versatile is a prized commodity for Appleton, Wisconsin based Norka, Inc. When management began searching for a new sheeting machine to handle greater workloads as a result of increased business, they narrowed the field down to two contenders. After testing, they chose and installed a new CHM 1700 precision sheeter from Colter & Peterson last July.

READ MORE

January 03, 2019

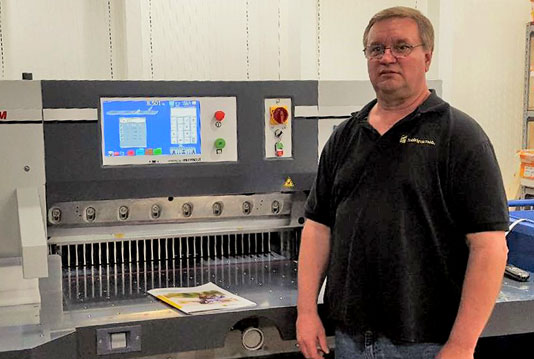

New SABER X-15 paper cutter from Colter & Peterson makes an Impression on San Diego trade printer

When you’ve been in the printing business for 30 years, you learn a few things. Mark Olsiewski certainly has. When the numbers at Impressions in Ink started to slide a bit in 2017, he proactively made some changes like investing in new equipment, something he had done previously to grow the business. Six months after installing a new 37-inch SABER® X-15 paper cutter from Colter & Peterson, he’s looking forward to more success in 2019.

READ MORE

December 20, 2018

Karr Graphics scores productivity, reliability benefits with new PRISM paper cutter

The fourth quarter in any football game is the most critical period, the one where decision making can win or lose the game. It’s the same for many printers such as Karr Graphics in New York City. Faced with a tough decision heading into their busiest time of the year, Larry Karr made a great call. He bought a new 36-inch PRISM® paper cutter with Microcut® from Colter & Peterson that has produced winning results since October.

READ MORE